Project Description

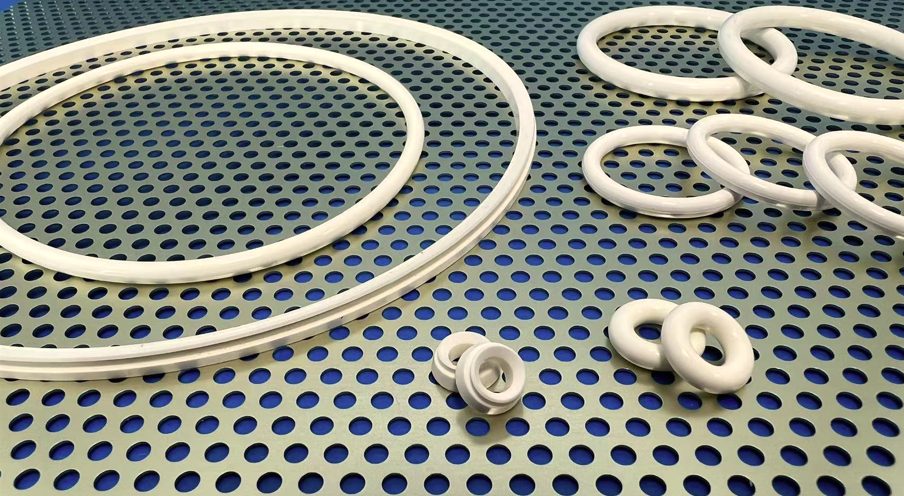

Semiconductor refers to materials that exhibit electrical conductivity properties between conductors and insulators at room temperature. Semiconductors find applications in integrated circuits, consumer electronics, IT systems, photovoltaic power generation, lighting, high-power power conversion, and various other fields. In semiconductor manufacturing equipment, sealing rings are crucial components. They are used to ensure the hermeticity of the internal environment, preventing dust, moisture, and other contaminants from entering the equipment and providing stable working conditions. Therefore, sealing rings for semiconductor equipment need to meet a series of stringent requirements. Yonda Seal’s research and development of perfluoroelastomer (FFKM) sealing materials and products are renowned for their exceptional resistance to extreme temperatures, chemicals, and plasma environments.

Kameduraz® K83

High purity for dry etching resistance to plasma

Kameduraz® K83 is specifically developed for high-density plasma systems and diffusion processes, and its sealing reliability and minimal particle generation in actual equipment have been thoroughly validated. It exhibits excellent resistance to various corrosive chemical media and is designed with multiple shapes and cross-sections to meet the requirements of various dynamic or static dry etching processes, particularly for valve seals. Kameduraz® K83 can also maintain stability at operating temperatures up to 210°C and is suitable for wet etching and cleaning processes.

Features and Advantages:

- Ultra-high purity

- Outstanding chemical corrosion resistance

- Excellent physical properties

- Low metal ion leaching

Recommend for use in the following processes:

- Deposition (CVD, PECVD, RPCVD, HDPCVD, APCVD, SACVD, DCVD)

- Diffusion

- Oxidation (LPCVD)

- CVD, PVD, sputtering, evaporation

- Dry plasma etching

- Dry ashing

- Ion implantation

- Implant annealing

- Rapid Thermal Processing (RTP)

- Wet etching, cleaning

| Typical Properties | |

| Color | White |

| Gravity | 2.02 |

| Hardness (Shore A) | 70 |

| Tensile strength (Mpa) | 27 |

| Elongation at break (%) | 180 |

| Tensile modulus (Mpa) | |

| M100 | 11 |

| Compression set (%, 70h @ 200) | 23 |

| Temperature range | -20 to 210 °C |

Kameduraz® K315

Common type, high purity, resistant to fluorine plasma

Kameduraz® K315 is suitable for semiconductor equipment that demands high cleanliness and reliable sealing performance in dry etching processes. It is widely used in static plasma, photolithography, and diffusion processes. Operating with excellent tolerance and sealing performance, this product performs exceptionally well in working environments with temperatures not exceeding 210°C and under non-high-load conditions.

Features and Advantages:

- Good plasma tolerance

- Ultra-high cleanliness

- Wide compatibility and universality

- Low metal ion leaching

Recommend for use in the following processes:

- CVD, PVD, sputtering, evaporation (CVD, PECVD, RPCVD, HDPCVD, APCVD, SACVD, DCVD)

- Dry plasma etching

- Plasma cleaning

- Dry ashing

- Ion implantation

- Implant annealing

- Rapid Thermal Processing (RTP)

| Typical Properties | |

| Color | White |

| Gravity | 2.2 |

| Hardness (Shore A) | 70 |

| Tensile strength (Mpa) | 20 |

| Elongation at break (%) | 170 |

| Tensile modulus (Mpa) | |

| M100 | 8.0 |

| Compression set (%, 70h @ 200) | 17 |

| Temperature range | -30 to 210 °C |

Kameduraz® K19

Suitable for PECVD/ALD/HDPCVD and plasma etching

Kameduraz® K19 is an amber-colored translucent product designed specifically for PECVD, ALD, HDPCVD, and semiconductor processing etching processes. Kameduraz® K19 is engineered for demanding plasma environmental conditions, exhibiting corrosion resistance and low particle generation characteristics. It features excellent thermal stability, extremely low gas release, outstanding elastic recovery, and good mechanical strength, making it highly suitable for static and dynamically sealed applications under specific conditions. The recommended maximum application temperature is 260°C. It is important to note that all Kameduraz® K19 products undergo strict quality control for cleanliness, ensuring ultra-high purity and low metal ion leaching.

Features and Advantages:

- Excellent oxygen-fluorine plasma tolerance

- Outstanding chemical media resistance for dry processes

- Excellent thermal stability

- Extremely low gas release and metal ion leaching

- Outstanding elastic recovery and low permanent compression deformation

Recommend for use in the following processes:

- HDPCVD, PECVD, SACVD

- Etching

- Ashing

| Typical Properties | |

| Color | Amber |

| Gravity | 2.06 |

| Hardness (Shore A) | 65 |

| Tensile strength (Mpa) | 28 |

| Elongation at break (%) | 220 |

| Tensile modulus (Mpa) | |

| M100 | 3.0 |

| Compression set (%, 70h @ 200) | 20 |

| Temperature range | -40 to 260 °C |

Kameduraz® H801B

| Typical Properties | |

| Color | Black |

| Gravity | 1.99 |

| Hardness (Shore A) | 77 |

| Tensile strength (Mpa) | 22 |

| Elongation at break (%) | 166 |

| Tensile modulus (Mpa) | |

| M100 | 13 |

| Compression set (%, 70h @ 200) | 15 |

| Temperature range | -10 to 315 °C |

Copyright Notice: © [2023] [Yonda Seal]. All rights reserved.

This article is protected by copyright law. No part of this publication may be reproduced, distributed, or transmitted in any form or by any means without the prior written permission of the author, except for brief quotations in reviews.

For permissions, contact [Yonda Seal] via [[email protected]].